REL's SURE-Torque Module

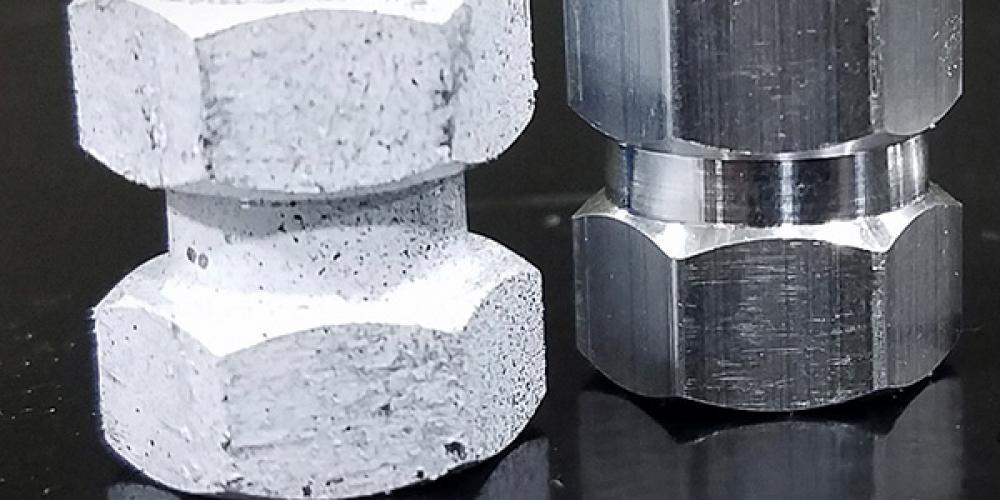

REL has enhanced the abilities of the SURE-Test Systems Platform. A new module, SURE-Torque, is a torsion module that has been developed to obtain shear properties of materials at high strain rates.High strain rate shear properties are important for engineers designing products subject to high energy events. Many engineers estimate shear properties from tension and compression tests, while others have derived creatively shaped samples to test shear properties with a compression SHPB setup. REL uses a hex shape on the ends of the bars and broached impedance matched couplings to apply the torsional loads to samples. See the machined and prepared samples and couplings below.

REL SURE-Torque Samples

To load a sample directly (and only) in shear, a torsion module was designed. This module required a total redesign of the loading mechanism.A servo motor was attached to a planetary gear box to develop enough torque to twist a 3/4” diameter bar is installed on the end of the incident bar. A clamp is used to hold the bar during the twisting of the bar to a predetermined torque (up to 600 ft-lbs). The clamp is then released suddenly to send a shear wave down the incident bar.

For calculations and testing, it should be noted that shear waves have a slower velocity and shorter wavelength than longitudinal waves of the same frequency. Typical shear wave velocity in steel is approximately 3250 meters per second (0.128 inch per microsecond). Longitudinal waves travel the fastest of the wave modes, approximately 5900 meters per second (0.23 inches per micro-second) in steel.

Once the wave reaches the end of incident bar, it impacts the sample. Much like conventional compression or tension SHPB testing, part of the wave travels through the sample into the transmission bar and part is reflected back into the incident bar.

Shear strain gages mounted on each of the bars capture the event. A high-speed camera is needed to visually measure the sample strain. Sure-Pulse 1.14 has been updated to perform the shear data processing and torsion digital image correlation (DIC). A sample DIC with strain tracking video is below.

This added capability to the SURE-Test Family of Modules allow researchers to fully develop material models that require tension, compression and shear properties. Contact REL today to expand your materials testing capabilities.