REL, Inc. Automated Metal Etch Systems - Designed. Manufactured. Delivered. Supported.

Metal Etch processing designed for the 22nd century implemented now!

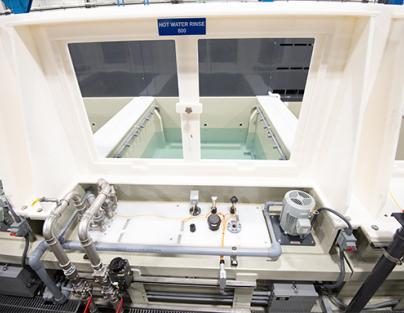

REL, Inc. designs, manufactures, and installs Fully Automated Metal Etch Systems. REL specializes in bringing dirty, and dangerous, manufacturing processes out of the dark corners of the aerospace industry and making them showcase processing centers for our industry partners' quality, precision, and part etching/cleaning effectiveness. We are America’s leading supplier of automated FPI processing equipment and are emerging as world leaders in providing automated chemical cleaning and metal etch solutions for the aerospace industry.

We do business right. We support our customers in their endeavors to provide the safest and most robust parts for the aerospace industry. We have been around for over 30 years and plan on being around for at least 100 more!

All Automated Metal Etch Systems are engineered and built at REL, Inc.’s World Headquarters in Calumet, Michigan. The Factory Acceptance Tests (FAT) are performed prior to shipment to ensure the equipment performs to our customer’s exacting specifications. With decades of automation experience, proper planning, and a highly trained team, REL provides installation quickly and effectively to minimize our customers’ downtime.

Features & Benefits:

- High throughput random loading of parts

- Web-based UI for maximum process visibility

- Designed specially to integrate with Allen Bradley PLC’s

- Real-Time Automated Tank Filling

- Dynamic Recipe Control

- Process in-situ designed safe processing checks

- On board PM Schedules and detailed work instructions

- Process viability and part processing historian

REL’s Automated Processing Lines are run on our comprehensive LOCKTIME Control Systems platform. Each automated line is controlled and monitored using an intuitive user interface. LOCKTIME stores user-specific recipes that can be selected and applied to individual baskets running simultaneously.

LOCKTIME Coho is the digital control system that represents the compilation of over a century of combined history in specific process control equipment. LOCKTIME Coho provides real-time and historical data from every system sensor with stakeholder-specific data. This data enables rapid training, troubleshooting, in-depth analytics, and compliance reporting.

The only thing better than purchasing a REL Automated Metal Etch System is the service and support that comes after the installation. Designed. Engineered. Manufactured. Installed. Supported.

For more information on REL, Inc.'s Automated Equipment, visit us at REL, Inc. World Headquarters; or call us at 906-337-3018.

RELentless Innovation.